Industrial Flooring Solutions in Las Vegas, NV

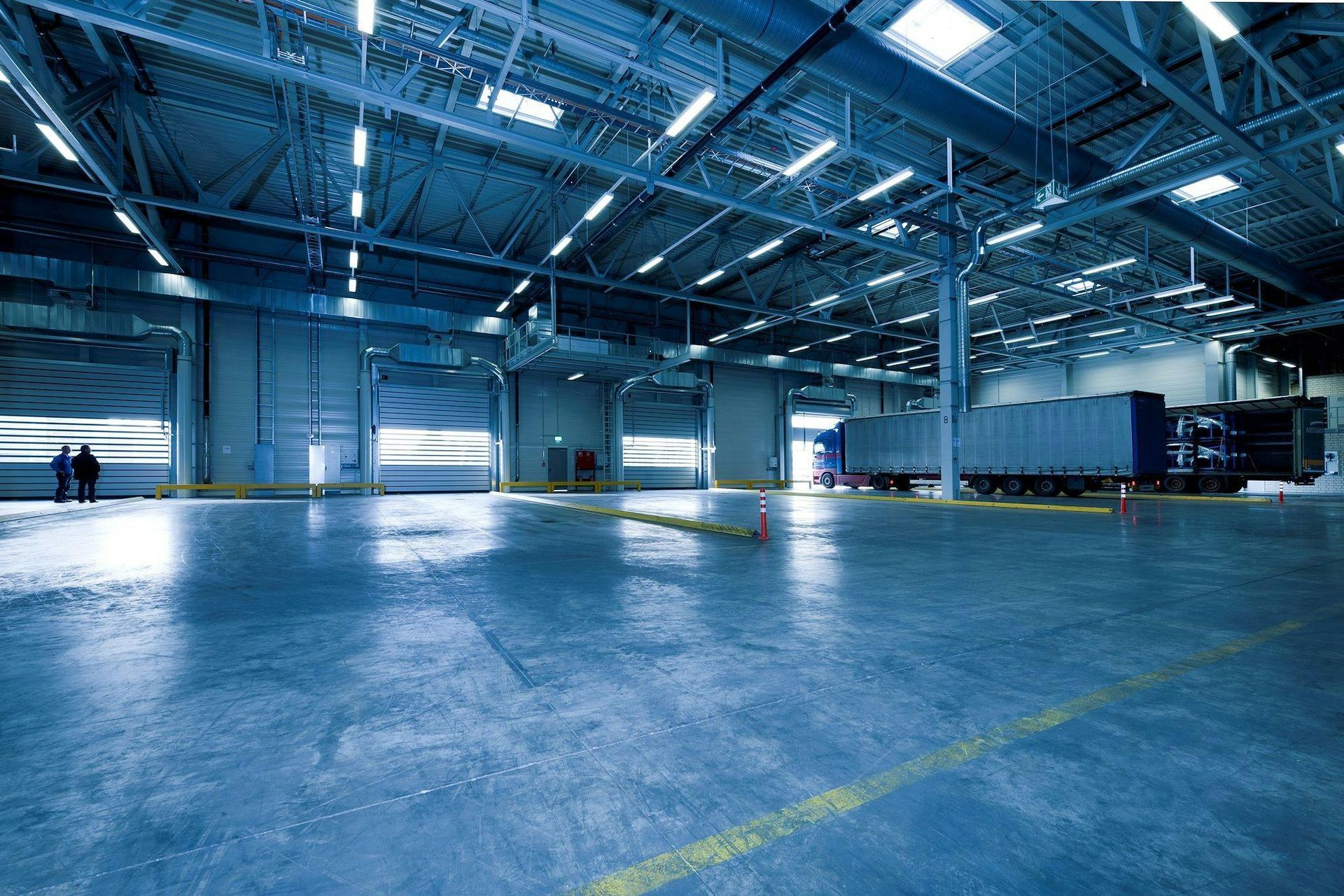

We deliver industrial flooring solutions engineered for the extreme demands of manufacturing plants, warehouses, and commercial facilities throughout Nevada. Our specialized team brings decades of experience creating surfaces that withstand the harshest operational challenges while enhancing workplace safety and efficiency.

Our industrial flooring systems are meticulously designed to endure heavy machinery, resist chemical exposure, and maintain integrity under constant traffic. We offer premium epoxy coatings, polished concrete, urethane cement, and hybrid systems—each precisely formulated to meet specific performance requirements for your unique facility.

Understanding that every industrial environment has distinct needs, we customize our solutions to address your exact specifications. Whether you manage a food processing plant requiring sanitizable surfaces, a logistics hub needing load-bearing durability, or a manufacturing facility demanding chemical resistance, our systems deliver exceptional performance.

Installation is executed with minimal disruption to your operations, with fast-curing options available when downtime must be limited. Our comprehensive approach includes thorough site evaluation, substrate testing, and tailored recommendations based on your facility's traffic patterns, equipment needs, and safety protocols.

We stand behind every installation with robust warranties and professional maintenance support, ensuring your industrial flooring delivers maximum value and performance throughout its extended service life.

Our Industrial Flooring Services

Las Vegas Flooring Company delivers professional-grade industrial flooring solutions engineered to withstand extreme conditions while maintaining safety and aesthetics.

Floor Installation

We utilize advanced preparation methods including diamond grinding and shot blasting to ensure proper adhesion and longevity of your industrial floor. Our certified installation teams follow strict protocols for moisture testing, surface profiling, and temperature control during application.

We incorporate expansion joint systems and flexible coating technologies to prevent cracking and delamination in high-stress areas. Our

installation process includes multiple quality control checkpoints and detailed documentation to guarantee optimal results.

Quality Materials

We exclusively use industrial-grade epoxy, urethane, and polyaspartic coating systems tested for superior chemical and impact resistance. Our materials meet or exceed ASTM standards for slip resistance, compressive strength, and wear characteristics.

Our anti-static flooring options protect sensitive electronic equipment while providing excellent durability. Each material we select is specifically matched to your facility's requirements for chemical exposure, temperature variations, and traffic patterns.

Custom Solutions

We design specialized coating systems around heavy machinery footprints and equipment mounting points to prevent floor failure. Our team creates custom patterns for safety zones, forklift paths, and designated work areas using highly visible line striping and symbols.

We engineer containment solutions for chemical storage areas and install specialized coatings beneath steel structures to prevent degradation. Our non-slip additives and texture profiles are precisely calibrated to your specific machinery and operational needs.

Repair and Maintenance

Our expert repair and maintenance services keep industrial floors performing at peak condition while extending their operational lifespan. We address issues promptly and implement preventive strategies to protect your investment.

Minor and Major Repairs

We specialize in resolving industrial flooring issues of any scale. Our team quickly addresses minor surface cracks and chips before they develop into serious problems. For extensive water damage or significant rot, we conduct thorough assessments to determine the best repair approach.

We perform section-by-section replacement when needed, matching materials and finishes perfectly with existing flooring. Our repair process includes surface preparation, material selection, and precise application techniques.

Preventive Measures

Regular inspections form the foundation of our preventive maintenance program. We identify potential weak points and early signs of wear before they affect floor performance.

We apply protective coatings and sealants specifically designed for industrial environments. These treatments shield against chemical spills, heavy traffic, and daily wear.

Our maintenance schedule adapts to your facility's specific needs and usage patterns. We recommend cleaning protocols and provide guidance on proper floor care between service visits.

Structural Integrity Services

Our expert team implements comprehensive measures to maintain the structural soundness of industrial flooring systems, addressing potential issues before they become major problems.

Underlayment and Joists

We begin by conducting thorough inspections of the underlayment condition using specialized equipment to detect weak spots and deterioration. Our team evaluates joist spacing and load-bearing capacity to ensure they meet industrial standards.

Regular assessment helps identify areas requiring reinforcement before installing new flooring materials. We measure deflection rates and verify proper support distribution across the entire floor system.

Floor Squeaks and Instabilities

We utilize advanced diagnostic tools to pinpoint the exact locations of squeaks and movement issues. Common causes include loose fasteners, warped joists, and separation between subfloor layers.

Our repair process includes securing loose

connections with industrial-grade fasteners and installing bridging between joists where needed. We apply specialized lubricants to reduce friction points causing noise.

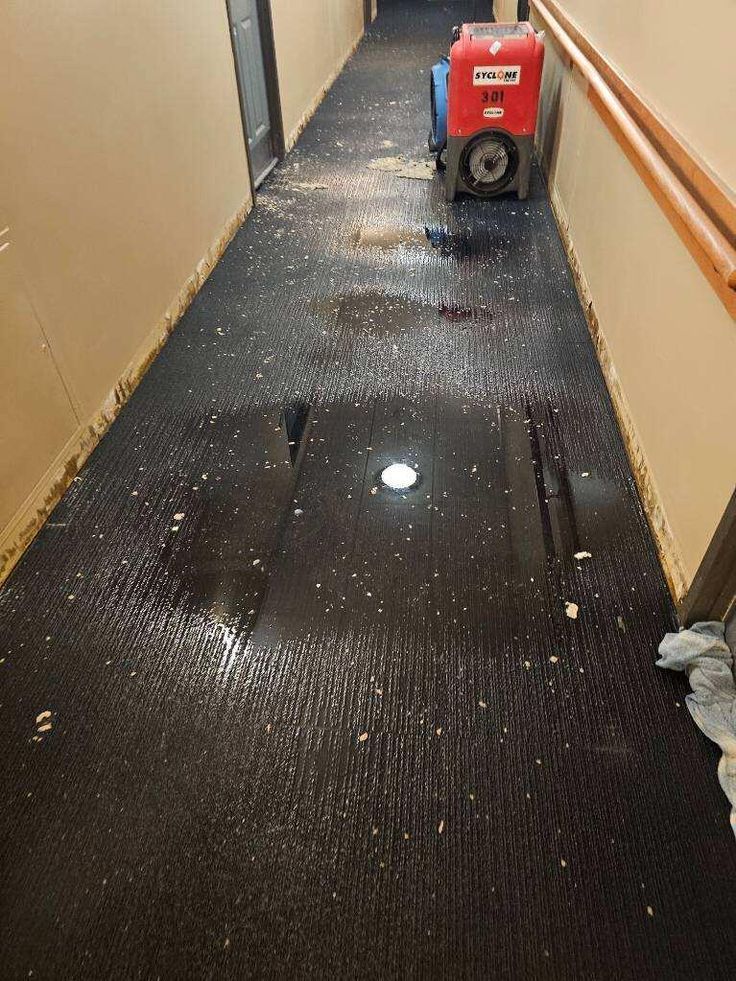

Water Damage

We employ moisture detection equipment to identify affected areas and assess the extent of water damage. Our team removes compromised materials and implements proper drying procedures.

Damaged sections receive specialized treatments to prevent future moisture issues. We install vapor barriers and waterproof membranes where necessary to protect against recurring problems.

FAQs on Industrial Flooring Solutions

Industrial flooring solutions require careful consideration of specific technical requirements, environmental conditions, and operational demands. Our team of experts addresses common inquiries about selecting the right flooring systems.

What is the best industrial flooring solution for a warehouse in Las Vegas?

Polished concrete or epoxy are typically best for Las Vegas warehouses. Polished concrete offers excellent durability and heat resistance for Vegas' extreme temperatures while minimizing dust. High-build epoxy systems provide superior chemical resistance and can be customized with anti-slip additives to enhance safety. For facilities with temperature fluctuations, polyaspartic coatings offer rapid curing and UV stability.

How quickly can industrial epoxy flooring be installed in Las Vegas?

Standard epoxy flooring installation typically takes 3-5 days in Las Vegas: 1 day for surface preparation, 1-2 days for application, and 1-2 days for curing. Fast-cure systems can reduce total time to 2-3 days. However, during summer months when temperatures exceed 100°F, installation may require night work or climate control measures. Projects over 10,000 square feet may take longer but can be completed in phases to maintain operations.

How much does industrial concrete polishing cost per square foot in Las Vegas?

Industrial concrete polishing in Las Vegas typically costs $3-$8 per square foot. Basic polishing starts around $3-$4 per square foot, while higher levels of aggregate exposure and shine can reach $5-$8 per square foot. Complex projects requiring extensive repairs or decorative elements may cost $7-$10+ per square foot. Large warehouses (10,000+ sq ft) often qualify for volume discounts.

What is the lifespan of industrial epoxy flooring in high-traffic areas?

Industrial epoxy flooring in high-traffic areas typically lasts 5-10 years before requiring significant maintenance. Heavy-duty epoxy systems with proper installation can extend lifespan to 7-15 years. Key factors affecting longevity include quality of preparation, epoxy thickness (minimum 20-30 mils for industrial use), maintenance practices, and traffic type. Regular maintenance can significantly extend useful life.

What flooring solutions work best for logistics warehouses in Las Vegas?

For logistics warehouses in Las Vegas, the best flooring solutions include:

- Polished concrete: Excellent for forklift traffic, minimizes dust, reduces tire wear, and reflects light to cut energy costs

- Epoxy systems: Provide clear lane markings, chemical resistance for battery charging areas, and customizable safety features

- Urethane cement: Ideal for loading docks with thermal shock concerns

- Hybrid systems: Combined epoxy/polyurethane topcoats offer balanced performance for varying warehouse zones

The best choice depends on specific operations, equipment types, and budget considerations.

Still have a question?

Interested in our services? We’re here to help!

We want to know your wood flooring needs exactly so that we can provide the perfect solution. Let us know what you want and we’ll do our best to help.